Not only did the substructure stay afloat despite the steel frame. It was then able to carry ALL OF THE BRICKS without sinking. In this photo there are 9 bricks, in total it carried 12. Putting that to scale, it would mean that at real life size, the substructure would be able to support a family of five without sinking.

Posted 15 May 2014 12:11

Testing the substructure at Sale Water Park. Was so happy when it actually floated. (Our model was really heavy, as it had a STEEL FRAME).

Posted 15 May 2014 12:06

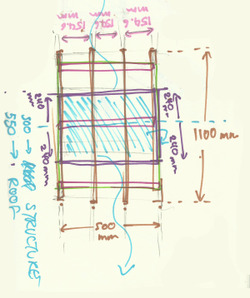

Sketch of the roof structure. The roof of the building would have a small pool which would be used for water storage. This water would then be filtered and used for drinking water for the people inside.

Posted 15 May 2014 12:03

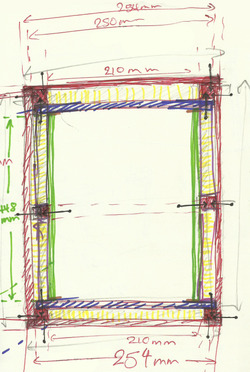

This sketch shows the design of the wall structure. The interior would be protected from water by polycarbonate sheets on each side. The material on the inside of the building would be flat panels of plywood which would have a space at the top which would have reused car tyres which let light into the building as well as provide space for storage. In between the plywood sheets and the polycarbonate sheets is a layer of insulation made out of bubble wrap. This is because one of the main aims of out project is to source materials which are very difficult to recycle, and then use these to build a flood resistant home.

Posted 15 May 2014 11:58

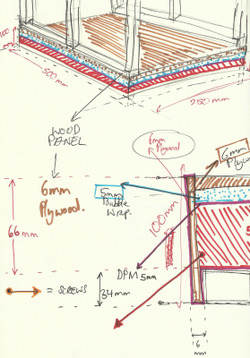

This sketch shows the basic design of the floor structure and shows the materials we would use. In reality the substructure also has a lightweight steel frame that surrounds it. The red hashed area is where the polyfoam would be placed, and beneath that is the space for the pipes that would aid in making the structure buoyant.

Posted 15 May 2014 11:41

This was one of the initial concept sketches for our floating building. It shows a space for water storage at the top and the possible entry method.

Posted 15 May 2014 11:33